Chamber Shaft Seal

|

The shaft seal type KD-4 HD is a labyrinth seal with solid chambers und seal rings which are radially flexibly mounted. The seal rings consist of several segments and are kept together by the garter spring. The seal rings are suitable for dry running and do not need any lubrication whatsoever. The material of the seal ring is chosen according to the operating conditions. Standard material is T10K. As a wear protection for the shaft, a surface hardness of minimum 60 HRC has to be considered. If the shaft does not have the necessary surface hardness, we recommend a shaft sleeve according to our norm file TWB 2 along with wear protection of quality FMP When in operating condition, the multi-part seal rings made from special carbon do swim on the high turbulent and high-energy gap stream without any direct contact to the shaft. Only with increased radial movements of the shaft, e.g. when passing the critical rotary speed, a short contact between seal ring and shaft may happen. With the help of special constructive measures it was achieved that the radial movement of the seal rings stay in full function even with a differential pressure Δp of 10 bar per seal ring. Consequently, the surface |

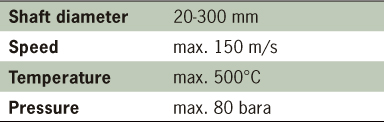

Compared to the rigid and contact-free labyrinth seals, the shaft seal TEDIMA KD-4 HD offers a considerablybetter efficiency especially with supercritical rotors. The leakage values are reduced by up to 90 %. The layout of a seal system of the ‘HD’ series is based on precise as possible details regarding maximum operating conditions and material characteristics. Hence it is necessary to have the completed design data sheet at hand with all necessary details when planning the shaft seal according to customers’ inquiries and orders. Technical Data |