Hygienic and Aseptic Seals – Keeping your process integrity at all time

The solution for controlled and reliable sealing of rotating movements with an absolute protection of (valuable) product, people and the environment. The dead-space free construction can be cleaned from the internal part of the seal by means of CIP and / or SIP. It is also possible to provide the seal with a sterile barrier for use in high-care aseptic and pharmaceutical applications. The condition of the seal can be carefully checked and monitored during its lifetime. A compressed air or barrier-gas signal reports the integrity "health" of the seal. This makes it possible to accurately monitor 24/7 the seal integrity and predict maintenance. No complex and costly subsystems are required, as is customary with traditional mechanical seal systems.

Application areas include process installations and machines where a rotating movement must be reliable, product-friendly and optimally sealed used in the following industries;

• Beer and soft drinks industry • Food industry • Pharmaceutical industry

Learn more about a case study for TEDIMA Advanced Hygienic Sealing Technologie at Sanquin Blutbank Amsterdam:

Application example for Advanced Hygienic Sealing

Product specifications

| Available sizes | Ø20 t/m Ø600 mm |

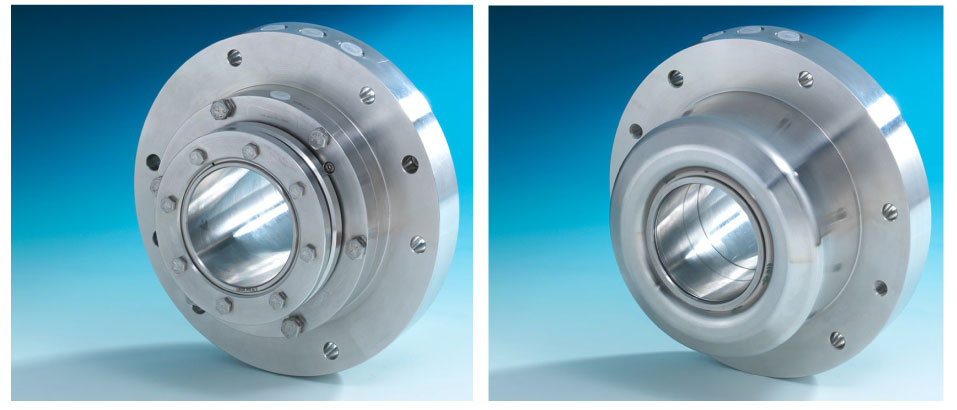

| Available designs | Clamped, flanged or as swimming execution With or without integrated support bearing |

| Design pressure | 1 up to 10 bar |

| Design temperature | -90°C up to +220°C |

| Housing | Standard Stainless Steel 1.4571 (316Ti), optional Duplex 1.4462, Hastelloy and Titan |

| Lip Seals | EdiFLON Super HP - TEDEX |

| Elastomer | EPDM, Viton, NBR, Silicone |

| Shaft protection | TMP70 - FDA |

| Certification | CE1935/2004, EU10/2011 and FDA |

| ATEX | Available for ATEX gas and liquid applications |

| Design classification | Aseptic Type EL - Aseptic CLASS I Hygienic Type EL - CLASS I |

Benefits and features

- Interchangeability with existing sealing systems

- Dead-space free construction towards product

- Cleanable with CIP / SIP, both internally and externally

- Can be provided with a sterile barrier

- Integrity controllable over the entire service life - Alert Status

- Suitable for pressure, vacuum or combined pressure / vacuum application

- Simplicity - keep it simple for service and maintenance

- Very attractive OPEX and TCO

- Excellent chemical resistance

- Wear-resistant and low frictional resistance

- Excellent dry-running properties

- No subsystems needed

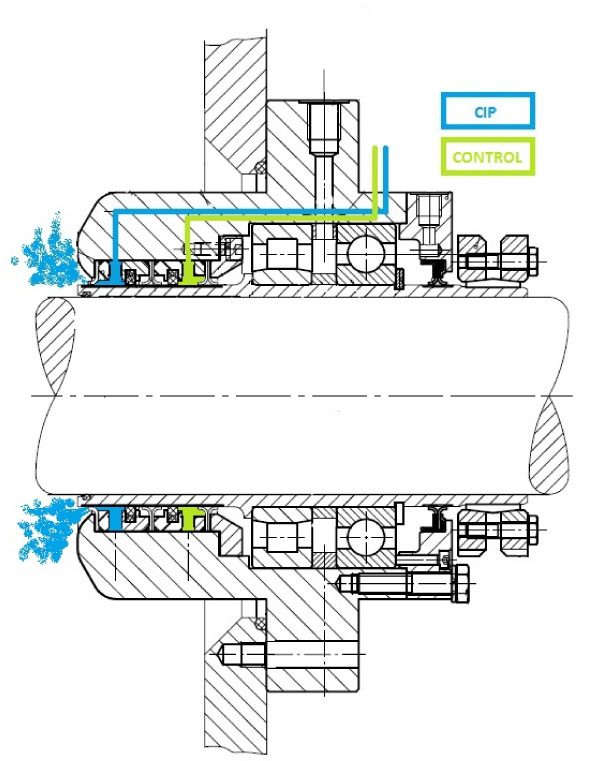

Working principle

The CIP / SIP connection is connected to a controlled branch of the CIP / SIP main line and runs along

with the normal cleaning process. Seal is hereby cleaned both internally and externally. By means of the

compressed air or barrier-gas control signal it is possible to check the integrity "health" of the seal 24/7.

If desired, it is possible to set a predefined alert status, being:

- Low alarm - Warning starting leak

- Medium alarm - Warning maintenance upcoming

- High alarm - Warning requires immediate maintenance