Universal Shaft Seal

The High Performance Shaft Seal

Constructional Features

Universal shaft seal rings are produced without metal housing and do basically consist of three elements:

- fabric-reinforced Elastomer to secure the seal rings against the casing bore.

- seal lips made from a homogeneous Elastomermixture with addition of PTFE (minor friction!)

- stainless steel garter spring

Application

Universal shaft seal rings are generally used in the engine construction, however, mainly with heavy equipment and shipbuilding (e.g. rolling mill, power transmission, propeller shaft, water turbine etc.).

In addition to the above, they are used where shaft seal rings in a metal housing may not be applied.

Universal shaft seal ringsare available in various types, in split and endless version.

Technical Data

Peripheral speed

With optimum operating conditions the universal shaft seal ring T51 can be used for peripheral speeds of max. 25 m/s. As for type T61, the allowed peripheral speed depends on the pressure load (Please see diagram).

Hardness of seal surface

Depending on the operating conditions 40 – 45 HRC.

Run-out and misalignment

Because of their construction, the universal shaft seals are able to accept high rotation and concentric deviations in the radial direction. The diameter and the peripheral speed are the decisive parameters.

The data and recommendations of this brochure represent our up-to-date knowledge and experience. Since there is a wide variety of possible applications, these data can merely be considered as a guidance. Warranty claims cannot be deduced thereof.

Pressure

The universal shaft seals T51 and T53 are only used in applications without pressure load. With pressure differences, type T52 can be used according to DIN 3769 depending on the rotating speed and peripheral speed (max. 0.5 bar).

Quality of seal surface

Special Versions

with dust lip

grooves and circular groove

Materials

Dimensions available

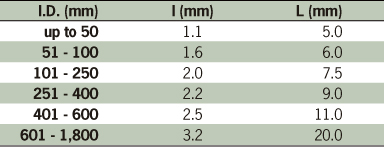

Installation dimensions

and tolerances